SMD2018貼片自恢復(fù)保險(xiǎn)絲

Performance Specification

|

Model

|

V max

(V dc)

|

Imax

(A)

|

I hold

@25°C

(A)

|

I trip

@25°C

(A)

|

Pd

Typ.

(W)

|

Maximum

Time To Trip

|

Resistance

|

|

Current

(A)

|

Time

(Sec)

|

R i min

(W)

|

R1max

(W)

|

|

SMD2018-030SF

|

60

|

10

|

0.30

|

0.60

|

0.9

|

1.5

|

3.00

|

0.500

|

2.300

|

|

SMD2018-050SF

|

60

|

10

|

0.55

|

1.20

|

1.0

|

2.5

|

3.00

|

0.200

|

1.000

|

|

SMD2018-075SF

|

60

|

10

|

0.75

|

1.50

|

1.1

|

8.0

|

0.30

|

0.110

|

0.630

|

|

SMD2018-100SF

|

15

|

35

|

1.10

|

2.20

|

1.1

|

8.0

|

0.40

|

0.060

|

0.360

|

|

SMD2018-100SF33V

|

33

|

35

|

1.10

|

2.20

|

1.1

|

8.0

|

0.40

|

0.060

|

0.360

|

|

SMD2018-150SF

|

15

|

35

|

1.50

|

3.00

|

1.1

|

8.0

|

0.80

|

0.050

|

0.170

|

|

SMD2018-200SF

|

10

|

35

|

2.00

|

4.00

|

1.1

|

8.0

|

2.40

|

0.030

|

0.100

|

V max = Maximum operating voltage device can withstand without damage at rated current (Imax).

I max = Maximum fault current device can withstand without damage at rated voltage (V max).

I hold = Hold Current. Maximum current device will not trip in 25°C still air.

I trip = Trip Current. Minimum current at which the device will always trip in 25°C still air.

Pd = Power dissipation when device is in the tripped state in 25°C still air environment at rated voltage.

Ri min/max = Minimum/Maximum device resistance prior to tripping at 25°C.

R1max = Maximum device resistance is measured one hour post reflow.

CAUTION : Operation beyond the specified ratings may result in damage and possible arcing and flame.

Environmental Specifications

|

Test

|

|

|

|

Conditions

|

|

|

|

Resistance change

|

|

|

Passive aging

|

|

|

|

+85°C, 1000 hrs.

|

|

|

±5% typical

|

|

|

|

Humidity aging

|

|

|

|

+85°C, 85% R.H. , 168 hours

|

|

±5% typical

|

|

|

|

Thermal shock

|

|

|

|

+85°C to -40°C, 20 times

|

|

|

±33% typical

|

|

|

Resistance to solvent

|

|

|

|

MIL-STD-202,Method 215

|

|

|

No change

|

|

|

|

Vibration

|

|

|

|

MIL-STD-202,Method 201

|

|

|

No change

|

|

|

|

Ambient operating conditions : - 40 °C to +85 °C

|

|

Maximum surface temperature of the device in the tripped state is 125 °C

|

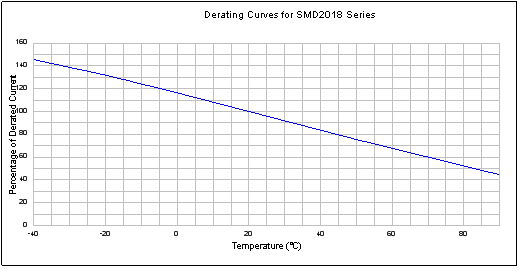

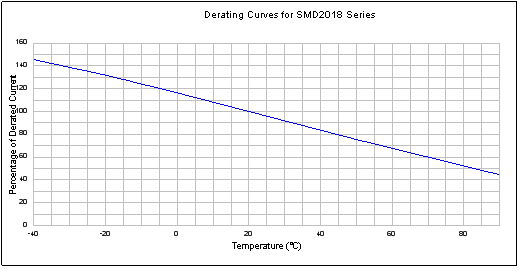

Thermal Derading Chart

Recommended Hold Current(A) at Ambient Temperature(°C)

|

Model

|

Ambient Operation Temperature

|

|

-40°C

|

-20°C

|

0°C

|

25°C

|

40°C

|

50°C

|

60°C

|

70°C

|

85°C

|

|

SMD2018-030SF

|

0.48

|

0.42

|

0.35

|

0.30

|

0.24

|

0.21

|

0.17

|

0.15

|

0.10

|

|

SMD2018-050SF

|

0.87

|

0.77

|

0.67

|

0.55

|

0.46

|

0.41

|

0.36

|

0.31

|

0.23

|

|

SMD2018-075SF

|

1.19

|

1.05

|

0.91

|

0.75

|

0.61

|

0.54

|

0.47

|

0.41

|

0.32

|

|

SMD2018-100SF

|

1.71

|

1.52

|

1.32

|

1.10

|

0.94

|

0.84

|

0.74

|

0.64

|

0.50

|

|

SMD2018-150SF

|

2.38

|

2.10

|

1.82

|

1.50

|

1.27

|

1.13

|

0.99

|

0.85

|

0.64

|

|

SMD2018-200SF

|

2.95

|

2.65

|

2.35

|

2.00

|

1.74

|

1.59

|

1.44

|

1.29

|

1.06

|

Thermal Derating Curve

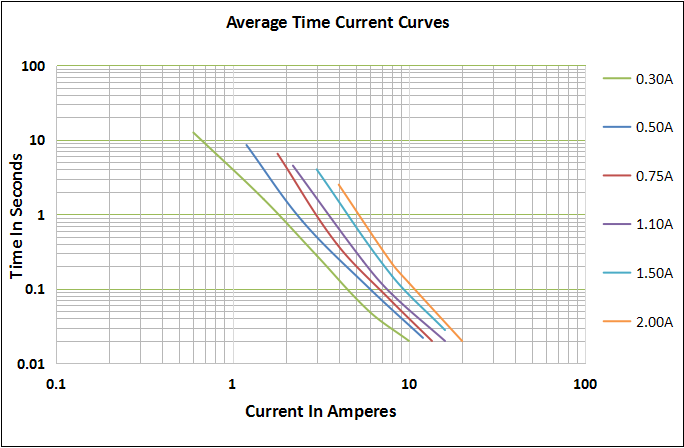

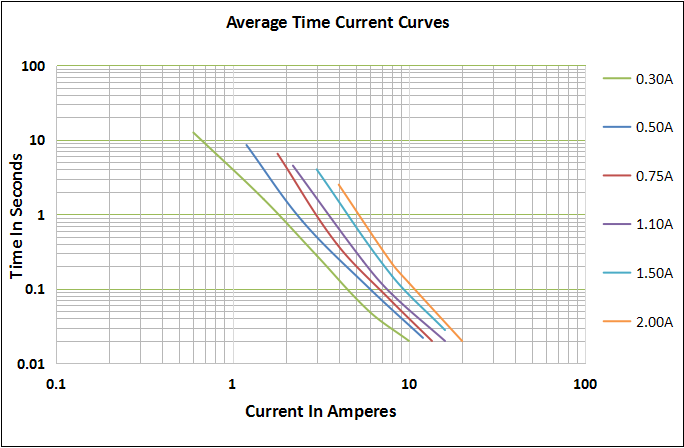

Average Time-Current Curve

Soldering Parameters

|

Profile Feature

|

Pb-Free Assembly

|

|

Average Ramp-Up Rate(Ts max to T p)

|

3℃/second mac.

|

|

Preheat

-Temperature Min(Ts min)

-Temperature Max(Ts max)

-Time(Ts min to Ts max)

|

150℃

200℃

60~180 seconds

|

|

Time maintained above:

-Temperature(TL)

-Time(tL)

|

217℃

60~150 seconds

|

|

Peak Temperature(Tp)

|

260℃

|

|

Ramp-Down Rate

|

6℃/second max.

|

|

Time 25℃ to Peak Temperature

|

8 minutes max

|

|

Storage Condition

|

0℃~30℃,30%~60%RH

|

Recommended reflow methods: IR, vapor phase oven, hot air oven, N2 environment for lead-free

Recommended maximum paste thickness is 0.25mm

Devices can be cleaned using standard industry methods and solvents.

Note 1:All temperature refer to topside of the package, measured on the package body surface.

Note 2: If reflow temperatures exceed the recommended profile, devices may not meet the performance requirements.

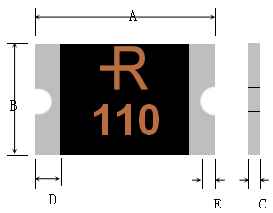

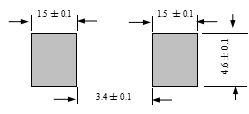

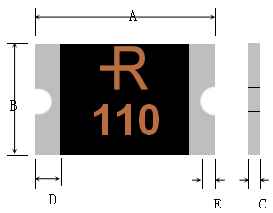

Physical Dimensions(mm.)

|

Model

|

A

|

B

|

C

|

D

|

E

|

|

Min.

|

Max.

|

Min.

|

Max.

|

Min.

|

Max.

|

Min.

|

Min.

|

|

SMD2018-030SF

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

|

SMD2018-050SF

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

|

SMD2018-075SF

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

|

SMD2018-100SF

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

|

SMD2018-100SF33V

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

|

SMD2018-150SF

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

|

SMD2018-200SF

|

4.72

|

5.44

|

4.22

|

4.93

|

0.50

|

1.20

|

0.30

|

0.25

|

Termination Pad Characteristics

Terminal pad materials:Tin-plated Nickel-Copper

Terminal pad solder ability:Meets EIA specification RS186-9E and ANSI/J-STD-002 Category 3.

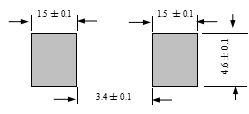

Recommended Pad Layout (mm.)

|

Tape And Reel Specifications (mm)

|

Governing Specifications

|

EIA 481-1

|

|

W

|

|

12.0 ± 0.2

|

|

P0

|

|

4.0 ± 0.10

|

|

P1

|

|

8.0 ± 0.10

|

|

P2

|

|

2.0 ± 0.05

|

|

A0

|

|

4.40 ± 0.10

|

|

B0

|

|

5.50 ± 0.10

|

|

B1max.

|

|

8.20

|

|

D0

|

|

1.50 + 0.1, -0

|

|

F

|

|

5.5 ± 0.05

|

|

E1

|

|

1.75 ± 0.10

|

|

E2min.

|

|

10.25

|

|

T

|

|

0.6

|

|

T1max.

|

|

0.1

|

|

K0

|

|

1.36 ± 0.1

|

|

Leader min.

|

|

390

|

|

Trailer min.

|

|

160

|

|

Reel Dimensions

|

|

|

A max.

|

|

178

|

|

N min.

|

|

50

|

|

W1

|

|

12.4 ± 0.5

|

|

W2

|

|

18.4 ± 0.5

|

|

|

|

|

|

Storage And Handling

|

|

? Storage conditions:0℃~30℃, 30%~60% R.H.

|

|

? Devices may not meet specified performance

|

|

if storage conditions are exceeded.

|

|

|

Part Number System

SMD 2018 - 口口口 S F 口口V

SMD 2018 - 口口口 S F 口口V

special voltage Rating(Optional)

Lead-Free

Tin-plated Nickel-Copper

Holding Current Rating

Device Dimensions: Length/width(Unit:1/100 inch) Size 5045 mm / 2018 inch

Surface Mount Device

東莞市富寬源電子有限公司(東莞市富源電子科技有限公司)成立于1998年��,主要從事安規(guī)元器件生產(chǎn)和銷售�,通過10年的改革和努力現(xiàn)在的富寬源已經(jīng)成為集生產(chǎn)和銷售為一體的安規(guī)元器件總匯���;富寬源將繼續(xù)秉持品質(zhì)第一�、服務(wù)客戶的原則不斷為廣大客戶提供質(zhì)優(yōu)價(jià)廉的產(chǎn)品�����。我公司目前主要提供如下產(chǎn)品:

電流保險(xiǎn)絲-CurrentFuse

玻璃管電流保險(xiǎn)絲

陶瓷管電流保險(xiǎn)絲

貼片電流保險(xiǎn)絲

電阻式保險(xiǎn)絲

微型電流保險(xiǎn)絲

高壓電流保險(xiǎn)絲

直流電流保險(xiǎn)絲

交流電流保險(xiǎn)絲

SMD-貼片式自恢復(fù)保險(xiǎn)絲

AI-插件式自恢復(fù)保險(xiǎn)絲

保險(xiǎn)絲座-Fuseholder

ESTMF系列保險(xiǎn)絲座

EDKFH系列保險(xiǎn)絲座

SKPTF系列保險(xiǎn)絲座

AUTO--汽車保險(xiǎn)絲座

OPWOP系列保險(xiǎn)絲座

拉線盒式保險(xiǎn)絲座

保險(xiǎn)絲夾&端子

保險(xiǎn)管座

保險(xiǎn)座

大電流|高壓保險(xiǎn)座

溫度保險(xiǎn)絲-Thermalcutoffs

方塊形溫度保險(xiǎn)絲

電阻式溫度保險(xiǎn)絲

大電流溫度保險(xiǎn)絲

陶瓷溫度保險(xiǎn)絲

鐵殼溫度保險(xiǎn)絲

SW.C溫度保險(xiǎn)絲

NEC溫度保險(xiǎn)絲

艾默生溫度保險(xiǎn)絲

內(nèi)橋溫度保險(xiǎn)絲

松下溫度保險(xiǎn)絲

AUPO溫度保險(xiǎn)絲

溫度開關(guān)/溫控器-Thermalprotector

熱保護(hù)器/可恢復(fù)溫控器

風(fēng)筒式溫控開關(guān)/溫控器

馬達(dá)熱保護(hù)器/溫控器

除霜除濕溫控器/溫控開關(guān)

超低溫溫控開關(guān)/溫控器

微型溫控開關(guān)/溫控器

溫度開關(guān)/溫控器-Thermalprotector

7AM/17AM溫控器

KSD301系列溫開關(guān)

KSD-01F插腳溫開關(guān)

9700系列方塊形溫控開關(guān)

BR系列溫控開關(guān)

SEKIST-22溫控器

壓敏電阻-Varistors

壓敏電阻

氧化鋅壓敏阻器

貼片壓敏電阻

SMD壓敏電阻

插件型壓敏電阻

高能壓敏電阻

汽車保險(xiǎn)絲Autofuse/carfuse

小號(hào)汽車插片保險(xiǎn)絲FY-MIN

中號(hào)汽車插片保險(xiǎn)絲FY-ATC

大號(hào)汽車插片保險(xiǎn)絲FY-MAX

小號(hào)叉栓式汽車保險(xiǎn)絲FY-UF

大號(hào)汽車叉栓式保險(xiǎn)絲FY-MF

管狀|柱狀汽車保險(xiǎn)絲

其他型號(hào)汽車保險(xiǎn)絲

過載保護(hù)器-CIRCUITBREAKER

AR1/AR2系列過載保護(hù)器

W系列過載保護(hù)器

88/88A系列過載保護(hù)器

90系列過載保護(hù)器

91/91L系列過載保護(hù)器

97/98/98H系列過載保護(hù)器

帶開關(guān)系列過載保護(hù)器

熱敏電阻-NTC/PTCThermistor

負(fù)溫度系數(shù)熱敏電阻

陶瓷正溫度系數(shù)熱敏電阻

高分子正溫度系數(shù)熱敏電阻

溫度傳感器

濕度傳感器

本公司將繼續(xù)通過ISO9000質(zhì)量管理體系的有效實(shí)施�,使涉及企業(yè)生產(chǎn)經(jīng)營(yíng)的各個(gè)運(yùn)作環(huán)節(jié),均嚴(yán)謹(jǐn)有序���,不斷制造出質(zhì)優(yōu)價(jià)廉�、適銷對(duì)路的產(chǎn)品參與市場(chǎng)競(jìng)爭(zhēng)���,使企業(yè)長(zhǎng)期保持較強(qiáng)的經(jīng)營(yíng)獲利能力�����。同時(shí)我們將長(zhǎng)期重視與行業(yè)知名企業(yè)合作�����,爭(zhēng)取最大限度的代理權(quán)�����,以最優(yōu)惠的價(jià)錢把產(chǎn)品銷售給客戶�����。